CPC Biomass Power Plant

At its Tema site, Cocoa Processing Company, requires a highly efficient power system consisting of biomass gasification and a combined heat and power (CHP) generation package using cocoa shells and pod husks as biomass fuel feed stock for optimum efficiency under a Captive Model.

- Location: Heavy Industrial Areaكوكولا 12345, Tema

- Client: Cocoa Processing Company [CPC]

- Output: 3.5MW, 24/7

* Steam minimum 12 tons per hour

* Hot Water

* Chiller (cold water including ice cubes) - Construction Started: 01/05/2020

- Estimated Completion: 16 months

Cocoa Processing Company Biomas Power Plant, Ghana

Captive Energy Co Ltd (CECOL) intends to finance, build and operate a Biomass to Combined Heat and Power using Cocoa Pod Husk as the main biomass feed for Cocoa Processing Company.

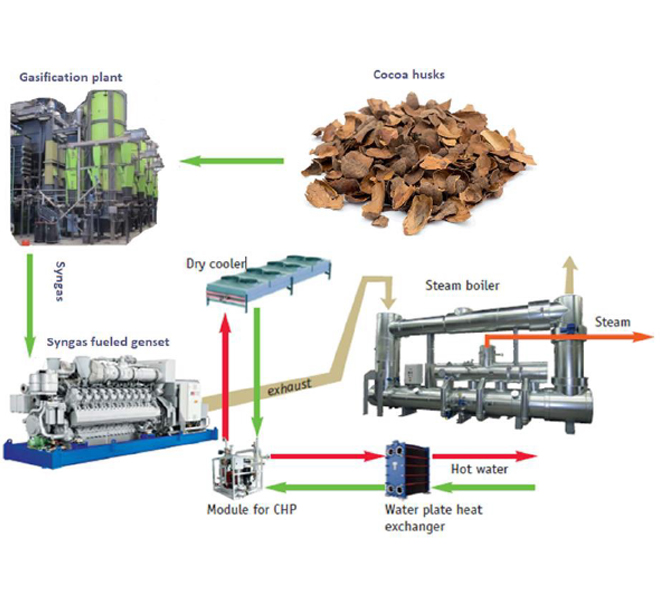

Process Technology

The Plant will use gasification technology to generate syngas to power Gas generators to generate electricity. The exhaust gas from the engine generators will be harnessed to produce steam, additional steam will be also be produced by a Biomass Boiler by direct combustion of a biomass boiler.

The project will use the latest Gasification technology known as Double Fluidized Bed Gasification technology. This technology has the highest Biomass to Thermal energy efficiency.

Plant Details

The gas Generators are equipped with unique control systems that enable the Gas generators to deliver optimum power from the varying composition of Gas molecules, thus providing maximum power for the minimum amount of fuel injected. Steam is derived from the Exhaust Steam boilers fitted to the Generators to produce both steam and hot water by using waste exhaust gases from the engine generators. To meet the steam consumption requirement, additional biomass boiler is installed to generate extra steam thorough direct biomass combustion.

Project Development Partners

- Captive Energy Co. Ltd.

- GP Green Energy

- Horus Energia

Project By-Products

- Fertilizer

- Charcoal